Prefabricated Package Pump Stations

BMS manufacture a comprehensive range of completely pre-fabricated GRP (Fibreglass) Pump Stations (Sumps) from 1000 l - 100,000 l capacity . All BMS Pump Stations are completely factory pre-fitted with guiderails/valves etc. They are available with or without separate valve chambers/24 hour emergency storage. They allow a far quicker installation and will save the costs/H&S risks/time associated with constructing and fitting a concrete sump on site.

How Do They Work?

BMS Pumps Stations are manufactured to customer requirements e.g. custom pipe inverts/sizes/types, internal pipework e.g. galvanised steel/electrofusion/ductile iron and pump fittings e.g. guiderails/non-return valves/stop valves etc. A range of station configurations are available; Vertical up to 25,000 l, Horizontal up to 100,000 l and Baffled Horizontal Stations with integrated emergency storage all with/without integrated valve chambers. Steel reinforced GRP options are also available that can be placed above/below ground, are fully portable and can be shipped in standard containers.

What Makes BMS Pump Stations Unique?

They allow a far quicker installation and will save the costs/H&S risks/time associated with constructing and fitting a concrete sump on site. BMS also have innovated a new range of container shippable Pump Stations mounted on skids, which are ideal for international projects such as oil, gas, mining and military camps and also for use with sewage treatment plant such as the BMS Blivet.

BMS offer a free Pump Station Design Service

If you have a project that requires a Package Pump Station, BMS offer a free no-obligation design service backed by our 40 years of Worldwide Experience. Once we know the pumping rate (l/s), pumping distance (m), static head (m) (the difference between the lowest and highest points on the rising main), the rising main type and diameter, we can use our custom software to select the best pump(s) to suit your requirements e.g. macerator or vortex pumps. We can then match this to our extensive range of pump chambers depending on the capacity your require to create a custom pre-fabricated pump station solution. We will not start manufacturing on the final drawings has received your approval. We can accommodate virtually any inlet/outlet pipe size/positioning.

Please contact BMS if you would like to discuss your package pump station project.

Typical Applications

Foul Sewage

Dirty Water

Surface Water

Advantages

Full Off-Site Manufacture

Delivered ‘ready to go’

Full customisable; Any inlet/outlet pipe size & positioning

Saves the cost and time of concrete sump and valve chamber construction

Integrated Emergency Storage

Separate Integrated Valve Chamber Option

Steel Framed Portable Option which can be place above/below ground

No Confined Space risk associated with fitting concrete sump

GRP is both rot & corrosion proof.

ISO 9001 Quality

Types of Pump Station

1. GRP Vertical Pump Stations

Vertical Pump Stations are available in a range of sizes from 1000 - 15,000 l capacity. These stations are an increasingly popular alternative to traditional concrete in situ chambers, which require fitting out on site. BMS Vertical Stations come fully pre-fitted and offer very quick installation/commissioning. They also offer great value compared to traditional in situ constructions. They can be used to pump both sewage and surface water. A separate valve chamber can be integrated into the top of the station if required.

2. GRP Horizontal Pump Stations

Horizontal Pump Stations are a great option when a large amount of emergency storage is required. BMS have specially designed a baffled option, with a wet well separated from the emergency storage by a full length baffle. A cut out in the baffle allows effluent to flow into emergency storage in the event of the wet well capacity being exceeded e.g. very high flow, power failure or pump fault. The baffle has a built in non-return valve at the bottom, which allows the return of effluent from emergency storage as soon as the wet well is pumped down. Capacities from 10,000 – 100,000 L are possible.

1. GRP Steel Reinforced Pump Stations

A. Horizontal/Balance Tank

The BMS Horizontal GRP Steel Reinforced option is typically used as a Balance Tank, to spread the flow coming into a sewage treatment plant over 24 hours. Tourist sites such as hotels and commuter housing developments normally have large peak flows in the morning and evening. All sewage treatment plants work best with regular smaller flows spread over 24 hours. BMS Balance Tanks ensure that flows are evenly spread and also protect the plant from non-biodegradable solids by a specially engineered internal baffle. They are available in a range of capacities from 10-60,000 L. BMS Steel Reinforced Pump Stations are portable and can be place above/below ground without a concrete surround.

B. Vertical Tank

The BMS Vertical Steel Reinforced GRP Pump Stations option is a unique and specially engineered option for shipping in a container. They are skid mounted and steel reinforced so that can be easily loaded/unloaded from containers. As with all BMS Pump Stations they are delivered fully assembled and ready to go with guiderails, chains etc. and with the option of detachable valve chamber. They are ideal for any site but especially for more remote sites like work camps & oil/gas fields.

4. Pumps

BMS are the main Irish Agents for Jung Pumpen, who are part of the Pentair Group and hand assemble all their pumps in Steinhagen, Germany. Jung Pumpen pumps are the finest available for pumping dirty water and wastewater. BMS can provide a complete pumping solution including control panels, GSM Dialouts, level controls etc. BMS can also provide Pump Stations/Pump Chambers for fitting by others or fully fitted with guide rails/pumps etc. by other pump brands/solutions.

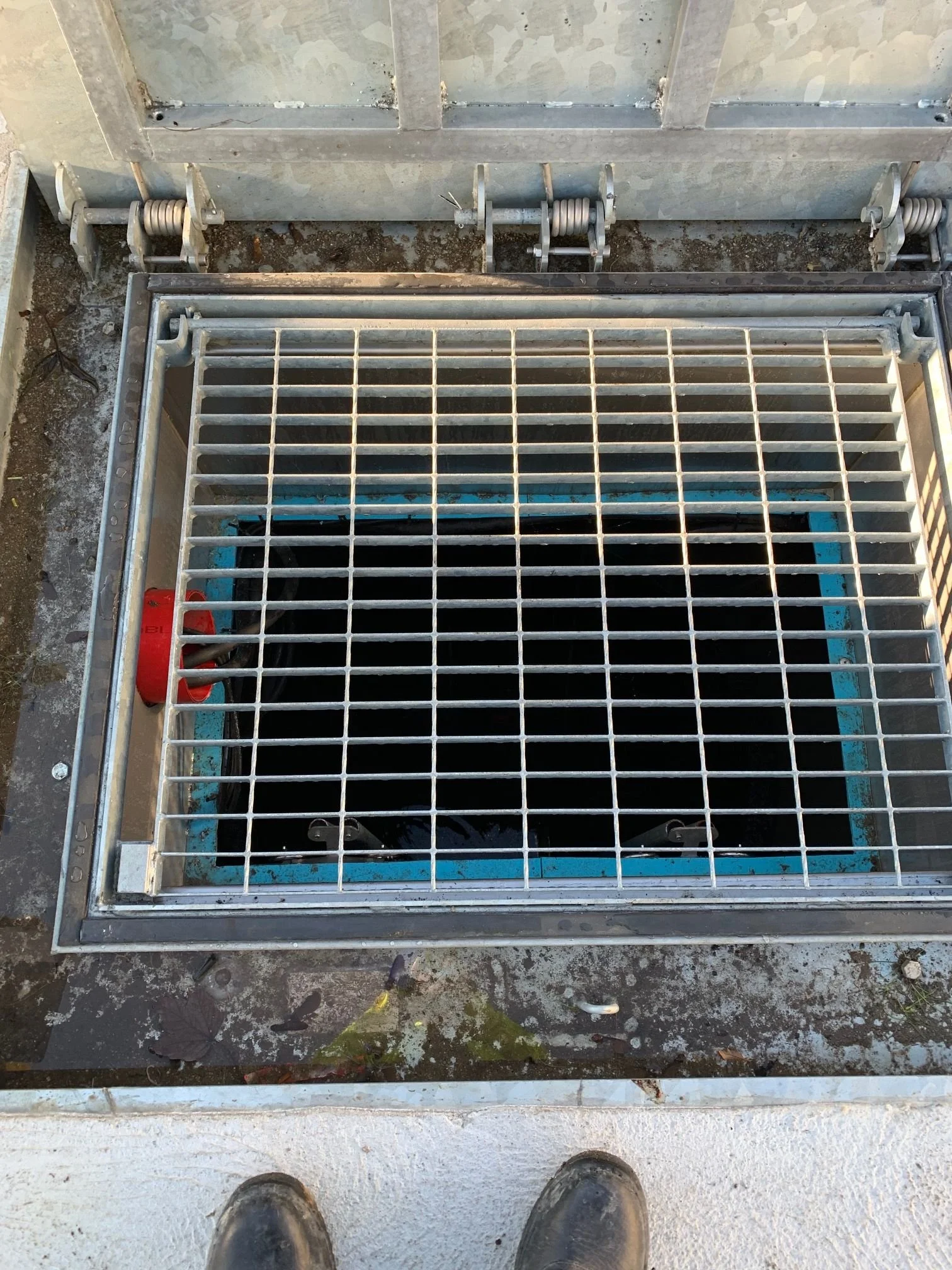

Installation

BMS Pump Stations are completely pre-fabricated and delivered ‘ready to go’ so siteworks are minimal; placing the station in a suitably sized excavation, connecting the inlet/outlet pipes & electrical ducts. BMS Pump Stations only require a complete a 225 mm of lean mix concrete surround and an appropriate non-weight bearing slab on top to suit the loading. It is then just a matter of connecting the power to the control panel, pumps and level controls. The steel framed version does not require a concrete surround above/below ground.

Materials

BMS Pump Stations are manufactured by BMS in our Irish World Class Manufacturing (WCM) facility under an NSAI validated ISO 9001:2015 Quality Management System. BMS Pump Stations are manufactured in rot/corrosion proof GRP/FRP (Glass Reinforced Polyester) using only Lloyds rated resins that have an expected life span of 50+ years. BMS Pump Stations are normally manufactured with corrosion proof electrofusion piping and steel guiderails to allow pumps to be accessed safely from ground level. BMS have innovated Valve Chambers that are integrated to the side of the unit and are detachable for transport if required.

BMS can also offer steel reinforced options, which are portable and can be placed above/below ground without a concrete surround.

BMS Pump Partner is Jung Pumpen of Germany who are part of the Pentair Group and in our 40 years of business manufacture the best dirty water pumps available.

About BMS

BMS is a quality manufacturer of package products for wastewater and stormwater treatment:

Established: 1986

Global Reach: Exported to over 60 countries.

Family Business: A third-generation company with deep expertise.

BMS Product Range

BMS provides a wide array of surface water and wastewater treatment products, including:

View the full product catalogue here

Additional Services by BMS

Free Design Service: For sewage treatment, pump stations, and surface water management.

Operation and Maintenance: Full services for existing installations, including repair, advice, and testing.

Free CPD Presentations: Available for sewage treatment and surface water management, delivered at your location.

We would be delighted to discuss any requirements you might have, and we are available to meet you at your convenience. Contact us today.

© Butler Manufacturing Services 2025.