Aerotor - Next Generation Rotating Biological Contactor (RBC)

The Aerotor® is a next generation Rotating Biological Contactor (RBC) (Biodisc) that combines fixed film reaction, active aeration, plug flow and intense surface area to yield a system that is three times more efficient than traditional RBC designs and has been installed in 1000+ locations worldwide over 35 years. The Aerotor has all the upsides of traditional RBCs such as process reliability, low operation, power and spare parts cost with none of the downsides such as large footprint, one sided/bridging growth issues & flow bypass during low/high flows. The Aerotor provides a highly efficient, low maintenance, high quality prefabricated solution to treat sewage from 20 to 5000 PE. The Aerotor is designed to work with new/existing primary & final settlement tanks. It is also highly suited to being added to existing plants where extra biological capacity is required.

Product Highlights↘ Next Generation RBC

↘ 3 x more efficient

↘ Most Compact RBC Available

↘ Very low operator/power/spare parts cost

↘ Does not require concrete surround

↘ Plug Flow

↘ Active Aeration

↘ Net Hydraulic Lift from inlet to outlet (gravity flow in/out)

↘ Proven over 30+ years in 40+ countries worldwide

↘ ISO 9001 Quality

What is the Aerotor Sewage Treatment Plant?

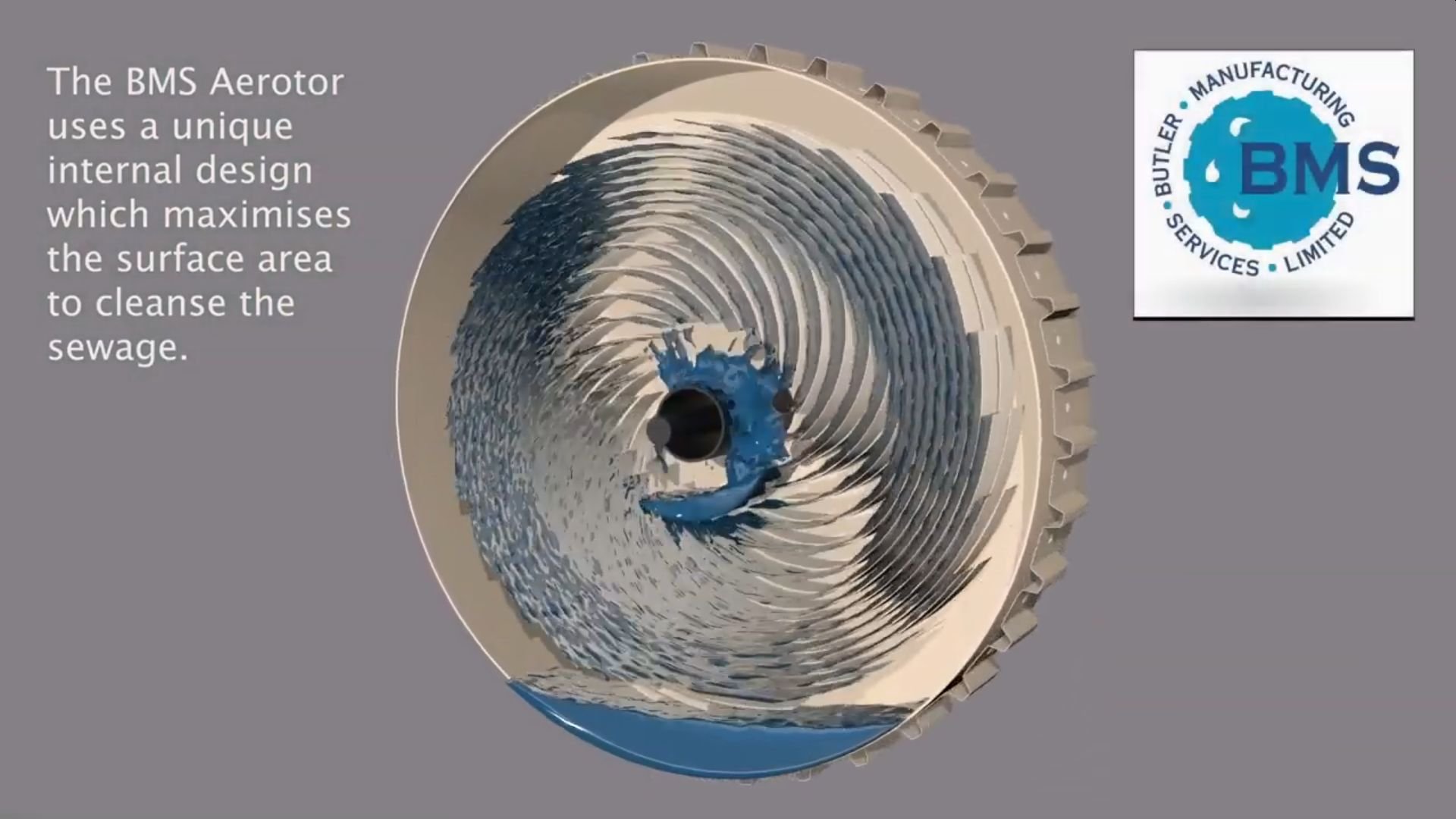

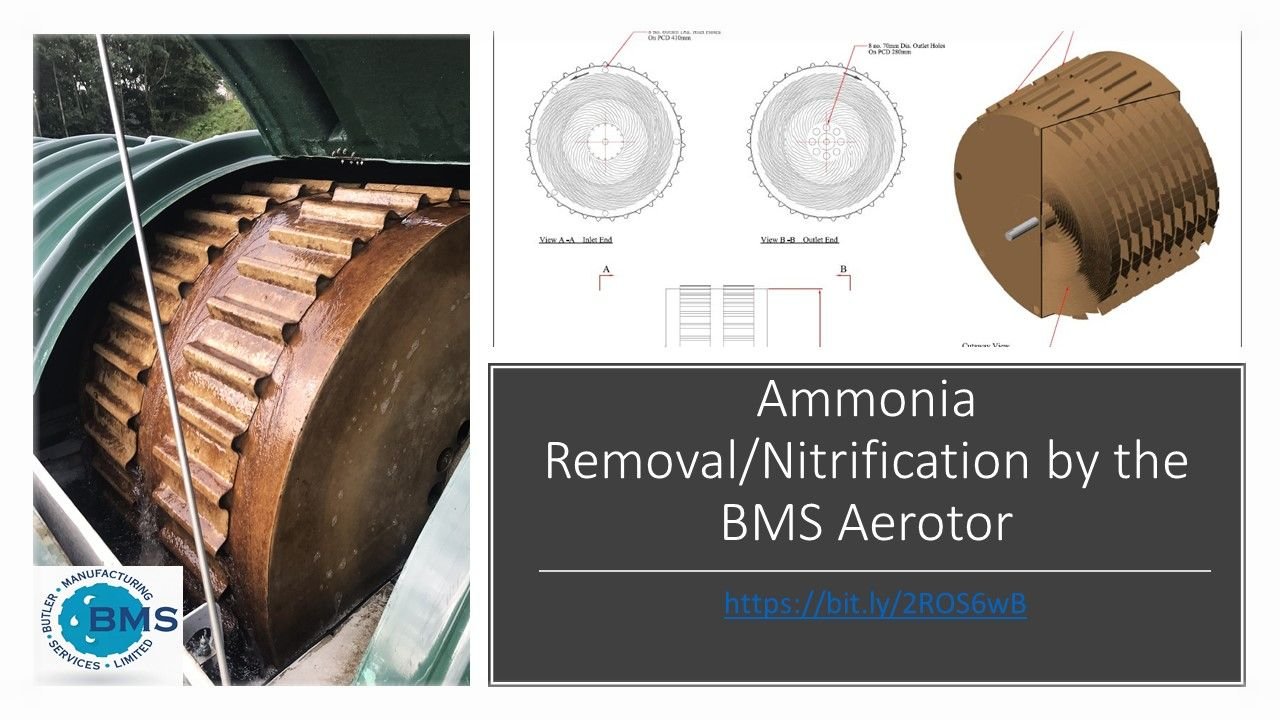

The BMS Aerotor is a next generation RBC; it is a combined fixed film reactor and active aeration system mounted on a horizontal shaft with 97% of the surface area inside the drum. The rotational GRP media is in a spiral formation enclosed in outer drum to provide active aeration, intense surface area and net hydraulic lift. The Aerotor is a plug flow system that can easily treat both high and low loads. It in essence has all the advantages of traditional RBC's; low power, maintenance, spare parts and operator input with none of the downsides such as one sided growth on shut down, excess biofilm growth and flow bypass during low and high flows. The Aerotor is a plug and play sewage treatment plant that can be placed above or below ground without the need for a concrete surround and is fully portable and relocatable.

The Aerotor® is designed to treat settled sewage in combination with in-situ or prefabricated primary and final settlement Tankage. It is often used to supplement existing underperforming/overloaded sewage treatment plants or for Ammonia Removal (Nitrification) where it can achieve Ammonia of less than 1 mg/l. The Aerotor can be installed above or below ground without the need for a concrete surround and is a complete plug & play system. It also generates 350 mm of net hydraulic lift from inlet to outlet meaning that it can be installed with minimal changes to existing pipework.

The Aerotor has a market leading track record; it has been installed in 40+ countries worldwide over 30 years in all imaginable temperature extremes.

The Aerotor is the biological heart of our market leading package sewage treatment plant; the BMS Blivet

The Video below shows how the Aerotor works as part of the BMS Blivet. It can also be installed on its own with separate primary/final settlement.

Advantages

|

Delivered ‘Ready to Go’ |

Extremely Compact |

|

Lowest Maintenance Requirement |

Robust Reliable Treatment |

|

Above/Below Ground Installation |

Permanent/Temporary Use |

|

Minimal Civil Works |

Fully Road/Container Transportable |

|

Unique Aerotor Technology |

ISO 9001:2015 Quality |

|

Unbeatable 30 Year Track Record in 50 Countries |

|

|

Full Irish/EU Design & Manufacture |

|

|

Full Design Support |

|

Model Selection

FEATURES

minimal maintenance

low running costs

temporary or permanent

above or below ground

net hydraulic lift

plug flow

compact

prefabricated "ready to go"

modular

APPLICATIONS

in combination with separate primary/final settlement

existing communal septic tank upgrades

chronically or seasonally overloaded works

tertiary treatment e.g. nitrification

phased development with modular units

trailer mounted for maintenance and emergency use

in-situ constructed work

About BMS

BMS is a quality manufacturer of package products for wastewater and stormwater treatment:

Established: 1986

Global Reach: Exported to over 50 countries.

Family Business: A third-generation company with deep expertise.

BMS Product Range

BMS provides a wide array of surface water and wastewater treatment products, including:

View the full product catalogue here

Additional Services by BMS

Free Design Service: For sewage treatment, pump stations, and surface water management.

Operation and Maintenance: Full services for existing installations, including repair, advice, and testing.

Free CPD Presentations: Available for sewage treatment and surface water management, delivered at your location.

We would be delighted to discuss any requirements you might have, and we are available to meet you at your convenience. Contact us today.

© Butler Manufacturing Services 2024.