Stormbreaker Defender - Hydrodynamic Vortex Silt/Oil/Debris Separator System

The BMS Stormbreaker Defender is a low footprint interceptor (separator) capable of removing silt, particles and floating pollutants such as oil/hydrocarbons/debris and contaminated settling solids from both upstream and downstream of surface or storm water flows. It can also be used before drain discharges direct in water courses to prevent pollution from silt and floating debris such as plastic bottles, bags, rags, cigarette butts etc.

Product Highlights

↘ 90% Total Suspended Solids (TSS) removal

↘ Plug & Play Technology; Minimal Civil & Installation Costs

↘ Effective Heavy Metal Particle Removal

↘ Separate Concrete Manhole Not Required

↘ Easy Maintenance from Ground Level

↘ No Power Requirement

↘ Self activating

↘ No Moving Parts

↘ Fits In a Standard Container/Truck for Transport

↘ Excellent Performance/Backup Data

↘ Full Irish/EU Design & Manufacture

↘ ISO 9001:2015 Quality

↘ Full Design Support

How Does it Work?

The Stormbreaker Defender has no moving parts and utilises natural vortex flow hydrodynamics. It has a unique internal geometry that removes silt/particles and captures floating pollutants/debris while minimising head-losses across the chamber. Effective heavy metal removal also takes place commensurate with particle size. It can be used upstream or downstream of surface water treatment systems such as attenuation or Sustainable Urban Drainage Systems (SuDS), ponds/reservoirs, holding tanks or before discharge to water courses as a means of pollutant removal.

Installation

The Stormbreaker Defender is ‘value engineered product’ that is delivered ‘ready to go’ and is simple to install for both new and existing applications. Simply lower onto a base via the integral lifting hooks, connect the inlet & outlet pipes and install a 225 mm leanmix concrete surround. A large separate concrete manhole is not required. The maximum unit diameter is 2.3 m meaning that all sizes can be uniquely delivered via a standard truck or container. Full installation instructions are available.

Design

The Stormbreaker Defender was developed by BMS in conjunction with the University of Ireland (NUI) Galway with the support of Enterprise Ireland. Extensive background research and full scale laboratory testing was conducted by an expert in the field of vortex dynamics resulting in a class leading ISO 9001:2015 Quality product fully manufactured and developed in Europe. It has extensive background data verifying both its selection and performance.

Materials/Manufacture

All BMS Stormbreaker Defenders are custom manufactured in corrosion/rot proof GRP (Glass Reinforced Polyester) using only CE marked materials and Lloyds rated resins in Ireland/EU under ISO 9001:2015 and have an expected lifespan of 50+ years.

To order a Stormbreaker Defender the following information is required:

Average Flow and Peak Flow through the unit e.g. 0.5 l/s – 250 l/s.

Inlet/Outlet Pipe Size

Flow Phases

The BMS Stormbreaker Defender utilises principles of vortex hydrodynamics to separate grit from storm water whereas baffles and weirs within the unit trap floatable pollutants. The induced vortex flow pushes heavy solids to the bottom of the unit and separates out floating pollutants via an internal pipe and weir. Low flow periods are a perfect time to inspect the unit to check the internal silt level. Should emptying be required this can easily be done with a suction tanker.

The Stormbreaker Defender can be used upstream or downstream of:

Sustainable urban Drainage Systems (SuDS)

Attenuation Systems

Ponds/Reservoirs

Holding Tanks

To remove debris such as cigarette butts, rags & plastic bottles before discharge to water courses

Maintenance

The Stormbreaker Defender is very easy to maintain with all maintenance from ground level. Full instructions are available.

Surface Water Design and One Stop Shop

BMS have over 30 years’ experience in sewage, wastewater and surface water design

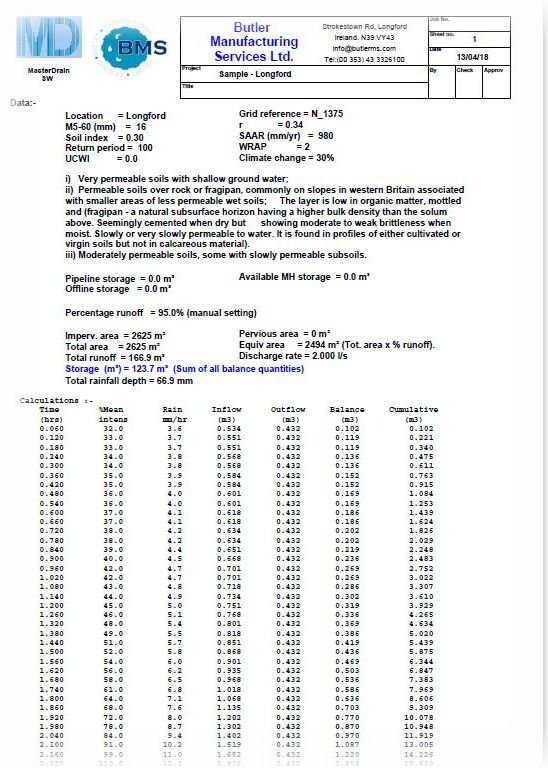

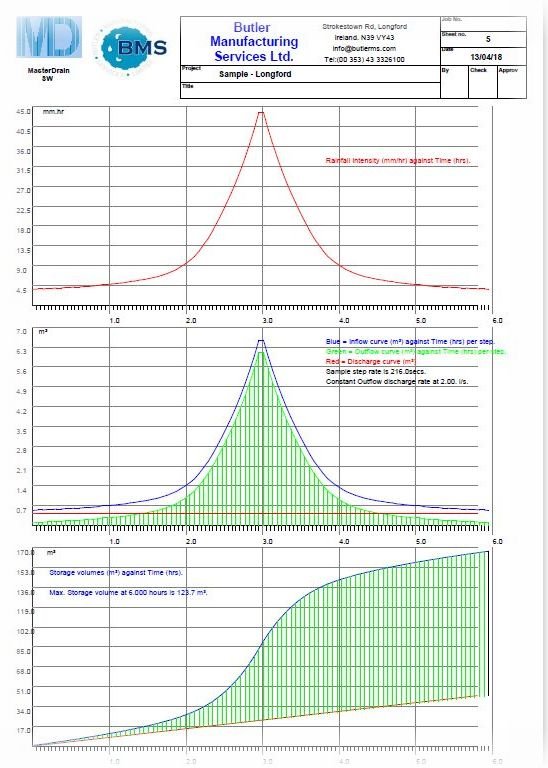

BMS can design your surface water management system and have invested in specialist software to provide cutting edge project design.

Design Services offered by the BMS

BMS can design your full surface water management or SuDS system from first principles.

BMS have invested in specialist software, which produces comprehensive design data. The design will include a full proposal, drawings and design calculations.

BMS can offer advise on sizing/selecting the correct attenuation/infiltration system, petrol/oil interceptor (separator), vortex silt/oil/debris defender, outlet flow controls & storage tanks.

BMS uniquely offer a ‘one stop shop’ from design to installation for our surface water management products.

All products are ISO 9001:2015 Quality manufactured in Ireland and Europe.

BMS offer free Continuing Professional Development (CPD) Seminars on Surface Water Management and Sewage Treatment at your premises.

BMS can design a custom pump station solution for your requirements in GRP/FRP. This can include emergency storage and valve chambers. BMS Pump Stations are normally delivered ‘ready to go’.

BMS can design a vehicle wash water recycling system for you with 100% Recycle and Zero Discharge.