Stormbreaker - Water Attenuation, Infiltration & Soakaway System

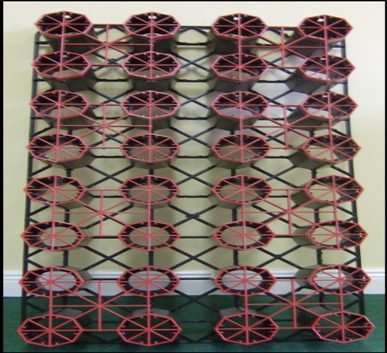

The BMS Stormbreaker® is an extremely strong Agrément certified storm water attenuation and infiltration system certified to CIRIA C737 with a 94% void. It can be installed quickly with no clips, minimal cover even under roads and can be transported in half the space associated with other systems. It is manufactured in certified Polypropylene under ISO 9001 in Ireland. The Stormbreaker also allows maintenance free installations i.e. no grit/silt entry to the system.

Product Highlights

↘ Extremely Strong; 843 kN/m2 certified.

↘ Excellent Performance/Backup Data

↘ Lightweight and easy to install

↘ 94% Void

↘ Installation depths 0.165 – 18.6 m

↘ Maintenance Free Installation

↘ Full Agrément Certification

↘ Community Registered Design

↘ Transports in 45% less space

↘ ISO 9001:2015 Quality

↘ Minimal Cover: 130 mm in Green Areas and 600 mm with HGV Loading

↘ Full Irish/EU Design & Manufacture

↘ Complete Off-Site Assembly Option Available

↘ Full Design Support

How Does the Stormbreaker Work?

The Stormbreaker forms an artificial underground reservoir where storm water can be stored and then released at a sustainable rate preventing flooding at the installation location and downstream in water courses and municipal sewers.

What makes Stormbreaker unique?

Its immense strength; its certified vertical loading is 843 kN/m2 (6 unit platen test). BMS have observed vertical loading in excess of 900 kN/m2 in product quality testing. To demonstrate this BMS commissioned a test where an 18 tonne fire truck was driven over one layer of Stormbreaker with only 130 mm of cover in the form of sand and paving brick. The video which can be seen below showed that the Stormbreaker did not move vertically or laterally or suffer any kind of structural damage despite the 18 tonne load and only 130 mm of cover.Its class-leading strength is derived from its unique arched rib design and interlocking installation pattern, which not only makes it extremely strong but also allows individual units to be lightweight, easy to manually lift and thus install.

You can see a demonstration of the Stormbreakers immense strength below, in a load bearing test, which BMS commissioned below, where a full laden Fire Engine reversed over a single layer of Stormbreaker multiple times.

Product Awards

Stormbreaker Materials/Manufacture/Certification

The Stormbreaker is one of most flexible products available on the market. The first layer is only 165 mm in height with subsequent layers 145 mm in height. It can be installed in any configuration from one layer to multiples of this deep including irregular shapes. Coupled with its extreme strength this makes the Stormbreaker the ideal choice for attenuation, infiltration, soakaways, under permeable paving/blue roofs and to form holding/storage tanks underground and even grassed trackways/roads.The Stormbreaker can be installed as a full sealed impermeable attenuation system e.g. 0.75 mm HDPE geomembrane surround/clay liner or as a permeable infiltration system e.g. non-woven geotextile 300 g/m2. BMS can advise on this and look after the whole process from design to installation/certification.A Demonstration Video Showing How Quick & Easy the Stormbreaker is can be seen below. A real time video can be seen at the following link.

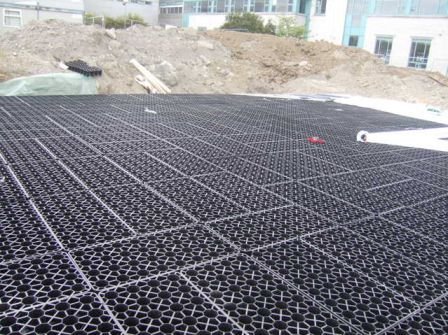

How is the Stormbreaker Installed?

The Stormbreaker is manufactured from only European sourced certified reprocessed polypropylene and is moulded in Ireland under an ISO 9001 Quality Management System. BMS designed the Stormbreaker and hold a Registered European Community Design for it.The Stormbreaker is fully Agrément certified to CIRIA C737 - Structural and geotechnical design of modular geo cellular drainage systems with a 50+ year expected design life. Agrément certification is the designated certification route for all building materials not subject to a specific European Directive. Certification provides validation on technical performance and load bearing. It be accessed at www.nsai.ie. A Demonstration Video Showing How Quick & Easy the Stormbreaker is can be seen below. A real time video can be seen at the following link.

How is the Stormbreaker Maintained?

The biggest concern of many planning authorities is the level of maintenance that will have to do after installation especially if they are taking it in charge after installation. BMS R&D Department innovated a new installation method to make Stormbreaker installations essentially maintenance free:

Install a stone base of 300 mm of 40 mm clean stone.

Run a perforated distribution pipe through the stone bed.

The pipe is surrounded with a permeable geotextile which allows the stormwater to infiltrate upwards into the Stormbreaker but prevents grit/silt entering the Stormbreaker system.

The Grit/Silt is washed through to the outlet manhole, so all maintenance takes place at the inlet/outlet manholes.

If combined with a BMS Petrol Interceptor and BMS Stormbreaker Defender Vortex Silt/Oil/Debris Separator virtually all grit/silt is removed before discharge.

Surface Water Design and One Stop Shop

BMS have over 30 years’ experience in sewage, wastewater and surface water design

BMS can design your surface water management system and have invested in specialist software to provide cutting edge project design.

Design Services offered by the BMS

BMS can design your full surface water management or SuDS system from first principles.

BMS have invested in specialist software, which produces comprehensive design data. The design will include a full proposal, drawings and design calculations.

BMS can offer advise on sizing/selecting the correct attenuation/infiltration system, petrol/oil interceptor (separator), vortex silt/oil/debris defender, outlet flow controls & storage tanks.

BMS uniquely offer a ‘one stop shop’ from design to installation for our surface water management products.

All products are ISO 9001:2015 Quality manufactured in Ireland and Europe.

BMS offer free Continuing Professional Development (CPD) Seminars on Surface Water Management and Sewage Treatment at your premises.

BMS can design a custom pump station solution for your requirements in GRP/FRP. This can include emergency storage and valve chambers. BMS Pump Stations are normally delivered ‘ready to go’.

BMS can design a vehicle wash water recycling system for you with 100% Recycle and Zero Discharge.