Package Sewage Treatment System Case Studies

Case Study on the treatment of sewage from a large construction site and its reuse using the BMS Blivet UV Package Sewage Treatment System.

Project Overview:

Butler Manufacturing Services Ltd. (BMS) were appointed by Roadbridge/Sisk to provide sewage treatment for all their construction workers and the site offices during the construction phase of the Center Parcs Longford Forest Project.

The project was the biggest single investment in Irish Tourism (€233 m) with Roadbridge appointed as the Main Civil Engineering Contractor and Sisk as the Main Construction Contractor.

Project Details:

COMPLETION DATE

April 2019

CLIENT

Roadbridge & J Sisk & Sons Ltd.

BRIEF

To design, manufacture, install and commission a robust turnkey low maintenance/operator BMS Blivet Package Sewage Treatment Plant to treat the sewage generated at a large construction site and disinfect to allow for non-potable reuse on site.

BMS worked with Roadbridge to produce an innovative version of its class leading Blivet Package Sewage Treatment Plant integrating UV disinfection at the outlet to make the treated effluent suitable for non-potable reuse on site. The Blivet UV was chosen as it offered a big advantage that instead of the very costly option of having to tanker untreated sewage away from site once/twice weekly for disposal at a large central works that the sewage was instead completely treated and disinfected on site and then reused.

Figure 1: BMS BL1000 UV No. 1 Center Parcs Longford Forest

The project had substantial environmental/financial benefits;

Ongoing Cost Savings;

A big cost saving of treating the sewage on site rather than tankering it away. The Blivet only needs to be desludged every three months.

Big Environmental Savings;

The elimination of once/twice weekly sewage removal to desludging once every three months.

Reduction in potable water use; the fully disinfected wastewater which consistently showed bacterial levels better than Irish bathing water standard, was reused on site for flushing toilets, road cleaning, dust suppression and wheel washing generating a huge potable water saving. A worker uses on average 30 l per day of water on site most of which is used for flushing toilets!

Decreasing the environmental footprint by reusing water in a closed loop.

Long Term Savings;

The Blivet is a fully portable ‘plug& play’ system that is ideal for temporary use and can be redeployed to other sites when a project ends, It is a completely self-contained true package sewage treatment system integrating primary/final settlement, aerobic treatment, 3 months sludge storage & UV disinfection. This is all housed in a steel framed GRP tank that is completely ‘plug&play’, does not require a concrete surround and can be placed fully above ground, partially/full buried. It uniquely generates net hydraulic lift from inlet to outlet meaning it enables gravity flow in/out without the need for extra pumping. Commissioning is as easy as connecting the inlet/outlet pipes and plugging in an electricity supply. Operator input is only 1-man hour per week. It can be easily lifted into place/removed/transported via Hi-Ab truck.

You can see how the Blivet works and its unique technology in the short 3D Video below;

BMS Blivet Design Details:

A BL1000 UV was selected for this project. This is typically a 100 Population Equivalent System. At its peak this Blivet treated up to 500 staff/workers on site. BMS offer a free design service to clients for both sewage treatment and surface water projects.

Figure 2: BL1000 UV Blivet Drawing

Figure 3: BL1000 UV Blivet being loaded via Hi-Ab

Figure 4: BMS BL1000 UV No. 2 Center Parcs Longford Fores

Figure 5: BMS BL1000 UV Disinfection Compartment

Final Effluent Results:

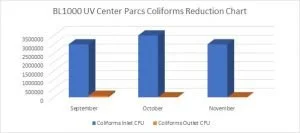

The Blivet performed exceptionally well over the nearly two years of its installation. Some sample results are below.

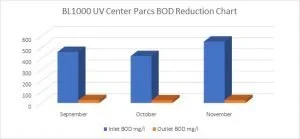

Figure 6: BL1000 UV Center Parcs BOD Reduction Chart

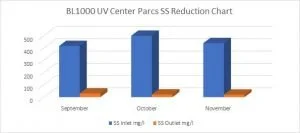

Figure 7: BL1000 UV Center Parcs SS Reduction Chart

Figure 8: BL1000 UV Center Parcs Coliforms Reduction Chart

Project Legacy/Future: Center Parcs Longford Forest was handed over by Main Contractors Roadbridge and Sisk in early July 2019. The success of the BMS Blivet UV was proven by the Main Construction Contractor Sisk also installing a BL1000 UV at the site to treat the sewage for their construction workers on site. 2 BMS BL1000 UV Blivet’s treated all the sewage generated by all the workers on site which peaked at 1000 and turned it into water suitable for non-potable reuse. Furthermore, the utilistation of the Blivet UV in the project was a Green Award 2018 Finalist. Overall the project provided a very quick pay back for both main contractors, substantially improved the environmental footprint of the project and created ongoing value; both the BL1000 UVs have now been redeployed to two other large construction sites doing the same job again. It’s a project we are very proud to have been involved in, especially since it is only 26 km from our factory door. Roadbridge and Sisk also should be commended on the fantastic job that they did.

What we learned:

Like any new concept unforeseen problems can occur. However, when they did BMS quickly solved them;

A glass sleeve protects the UV bulb from direct contact with treated effluent to be disinfected. If this becomes dirty it affects the level of disinfection. BMS initially installed a UV system with manual quartz sleeve cleaning on the advice of the manufacturer. It became clear over time that the sleeve required more regular cleaning than originally envisaged. BMS ethos has always been to minimise maintenance with automation. Therefore, a solution with automatic cleaning of the quartz sleeve was installed by BMS, eliminating the problem into the future.

A second issue is that the effluent generated on a site such as Center Parcs is closer to a full Population Equivalent than a normal office, as the workers on site are based there for the whole day rather than leaving at lunchtime as would be the case in most offices.

Finally, BMS pioneered another improvement where we integrated a control kiosk into the end of the Blivet, so all control panels are fully integrated into the Blivet, accessible from ground level and do not need to be disconnected when a Blivet is moved.

Figure 9: BL500 UV United Kingdom

BMS also manufacture a full range of products for surface water and wastewater treatment including our pioneering next generation RBC system the Aerotor, which form parts of our world leading Blivet package sewage treatment plant, a ‘one stop shop’ for all surface water products from design to installation including attenuation, interceptors, holding tanks (incl. chemical resistant), hydrobrakes, rainwater harvesting tanks/filters & vortex silt/oil/debris separators, fully fitted pumping stations, our plug & play vehicle wash water recycling system; the Recyclone and much more. Please see our enclosed Company & Product Profile for a full summary or View our full product/services catalogue at this link

BMS also can provide a Free Design Service for Sewage Treatment, Pump Stations or Surface Water and a full O&M, Repair, Advise and Testing service for existing installations. We also can do free CPD Presentations on Sewage Treatment/Surface Water Management at any location.

CAN’T FIND WHAT YOU ARE LOOKING FOR?

Talk To Us Today

At Butler Manufacturing Services, our staff and engineering teams are always ready and eager to help with any enquiry you might have. Whether you need guidance on product specifications or require a customized solution, our team is here to lend a helping hand.