BMS Blivet Package Final Effluent Polishing Filter (FEPF)

Introduction

The BMS Blivet® Package Final Effluent Polishing Filter (FEPF) is unique ‘all in one’ tertiary sewage treatment solution that can produce very high quality effluent suitable for discharge to the most sensitive environments. While it is compatible with any type of sewage treatment system, it is especially suited for use in conjunction with the BMS Blivet Package Sewage Treatment System. The system is completely self contained in a steel reinforced GRP/FRP tank. It does not require a concrete surround and is suitable for permanent/temporary use. It is now also possible to integrate a UV disinfection system into the unit to achieve the most stringent discharge standards and to produce highly treated disinfected effluent suitable for reuse e.g. irrigation. All Blivet FEPF systems can ship in a standard 40 High Cube Container/Megatrailer.

How Does it Work?

The Blivet FEPF uses a unique combination of filtration using Filtralite® and backwashing to reduce the Biochemical Oxygen Demand (BOD) and Suspended Solids (SS) to as low as 5 mg/l. As safe clean water is rapidly becoming one of the worlds most precious resources, the addition of an integrated Ultraviolet (UV) Disinfection Stage after the filtration, yields extremely high quality fully disinfected effluent suitable for immediate reuse e.g. irrigation, toilet flushing, cleaning, process water, vehicle washing.

What Makes it Unique?

The BMS Blivet FEPF is the most compact fully prefabricated ‘all in one’ Final Effluent Polishing Filter with integrated UV disinfection available. This package is a unique solution to polish treated sewage to the strictest international standards due to its ‘all in one’ ‘ready to go’ extremely compact design including UV Disinfection combined with its very low power and maintenance requirements.

The Picture below is an actual sample from the outlet of a large hotels Blivet FEPF!

|

Extremely Compact |

Lowest Maintenance Requirement |

|

Lightweight & Easy to Install |

Suitable for New/Existing Installations |

|

Optional Integrated UV Disinfection |

Minimal Civils Works |

|

Fully Road/Container Transportable |

Unique Package Design |

|

Minimal Civil Works |

ISO 9001:2015 Quality |

|

Full Irish/EU Design & Manufacture |

|

|

Full Design Support |

|

Product Highlights

Delivered ‘Ready to Go’

Extremely Compact

Lowest Maintenance Requirement

Suitable for New/Existing Installations

Above/Below Ground Installation

Optional Integrated UV Disinfection

Minimal Civil Works

Fully Road/Container Transportable

Unique Package Design

ISO 9001:2015 Quality

Unbeatable 30 Year Track Record in 50 Countries

Full Irish/EU Design & Manufacture

Full Design Support

Materials/Manufacture/Certification

The Blivet FEPF is manufactured by BMS in our Irish World Class Manufacturing (WCM) facility under an NSAI validated ISO 9001:2015 Quality Management System. It is manufactured in rot/corrosion proof GRP/FRP (Glass Reinforced Polyester) using only Lloyds rated resins that have an expected life span of 50+ years. The tank is reinforced with EN8 steel. All other parts including media, back wash pump and UV Disinfection system, are by manufacturers of international renown e.g. Saint Gobain, HQ Pumps and Ultraaqua. For ease of maintenance the standard Blivet FEPF has only one electrical part; a max 2.2 kW backwash pump, which normally operates for less than 20 minutes per day. The UV system, which runs 24/7 is rated at 0.2 kW and is self-cleaning. This means that maintenance takes less than ½ an hour per week. Due to the quality of manufacture, Blivet systems have an extremely low spare parts requirement and are built to last.

BMS Blivet FEPF Technology

The unit is an ‘all in one’ system designed to polish final effluent before discharge, removing residual BOD and SS left over at the end of a sewage treatment plant, with the option of integrated UV disinfection

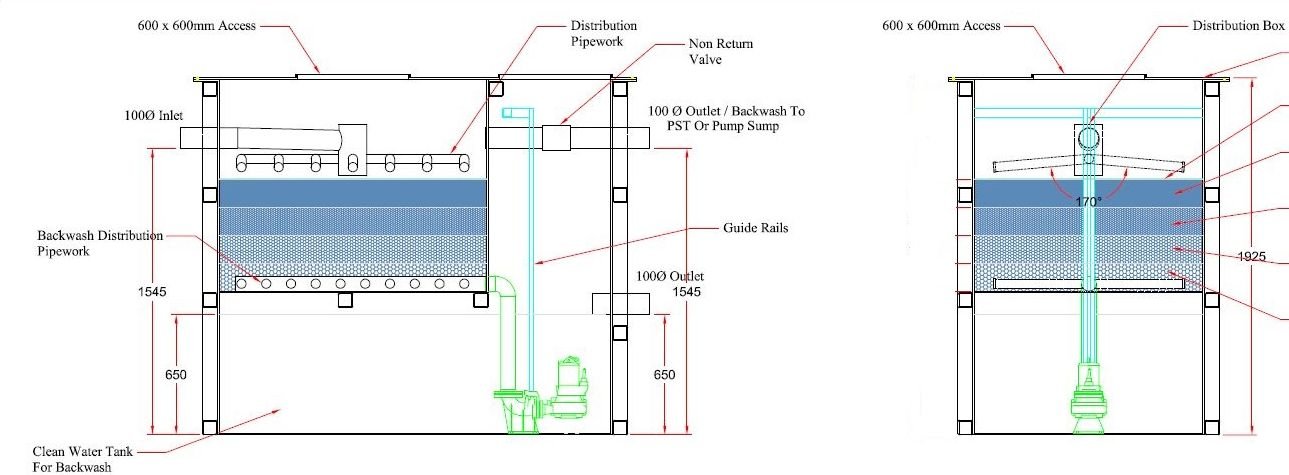

It consists of a steel reinforced GRP Fibreglass tank containing:

1. Distribution Pipework.

2. Filter Media.

3. Backwash tank, Backwash Pump and Backwash Channel.

4. Control Panel.

5. UV Disinfection System (optional)

1. Distribution Pipework

The treated effluent flows by either gravity or pumped flow into the distribution pipework. The standard inlet is 100 mm. If by pumped feed, pumping should be set to regular smaller amounts rather than larger once off amounts. The pipework is specially designed to ensure even distribution over all the whole media area. It consists of 50 mm slotted PVC channels at right angles to the central distribution pipe.

2. Filter Media.

The BMS FEPF uses a filtration bed of market leading Filtralite® media, which was specially selected to provide maximum filtration and at the same time to minimise the chance of blocking. It is combined with additional first stage of filtration provided by a unique hard-wearing filtration material with a 0.7 micron gap, Saran. The Saran also secures the filter bed in place. Filtralite is made of expanded, clay granules that are crushed and sieved. The porous, sharp-edged grains have strong resistance against mechanical abrasion and low acid solubility. Filtralite® is an inert, ceramic material and complies with the requirements of EN 12905 (Products used for treatment of water intended for human consumption expanded aluminosilicate). At the bottom of the chamber is collection pipework to collect the now filtered effluent. Over time the filtration grows as the trapped solids act as an extra filtration layer.

3. Backwash tank, Backwash Pump and Backwash Channel.

In keeping with BMS philosophy of producing added value package products that are ‘all in one’ and completely self-contained, a backwash reservoir had been built in under the filtration zone. This treated effluent collects in the chamber and then overflows via the outlet pipe to the discharge point. The treated effluent stored in the chamber is used to backwash the media, thus negating the need for an extra fresh water supply, as is the case with many similar systems. A powerful backwash pump is fitted in the backwash chamber, which is connected to the effluent collection pipework at the bottom of the media chamber. The pump when switched on, pumps the treated effluent through the media layer from the bottom dislodging trapped solids and cleaning the media. The backwash then flows back to the start of the treatment plant via a 150 mm backwash pipe at the top of the filter.

4. Control Panel/Electrical

The BMS Final Effluent Polishing Filter (FEPF) normally operates by gravity. The only electrical part is a fully integrated backwash pump, which operates on a fully automatic basis via a timer. The timer can be set to come on up to 12 times per day. Normally the Final Effluent Filter is set to backwash 1-2 times per day, to minimise power usage. The pump can also be operated via ‘Hand-Off-Auto’ switch. The FEPF also has high level protection to prevent blockage. If the media becomes clogged and the level rises in the filtration media chamber the backwash pump will automatically switch on to clear the blockage. The control panel is equipped with a flashing beacon, which switches on in the case of a high level in the media chamber of the backwash pump tripping. This can be linked to a GSM Alarm system or a Building Management System if required.

The pump is rated at 2.2 kW. Each back wash only uses less than 100 watts of power.

5. Disinfection

Further enhancing the value of the Blivet FEPF, is the optional addition of a high quality ‘Ultraaqua MR1-220 SS UV Disinfection Unit’ located in a discrete compartment at the end of Blivet FEPF, thus offering the most compact ‘all in one’ Final Effluent Polishing Filter available worldwide producing high quality disinfected effluent. The UV system is designed to deliver effective UVC doses calculated using peak flow rates and conservative estimates for water UVT. Doses are calculated at the end of lamp lifetime and include reductions for limited quartz sleeve fouling. The system has an integrated wiper mechanism. To enable the addition of the UV disinfection system the total height of the system increases to 2.6 m in height and 3.9 m in length. This can ship in a High Cube Container or on Megatrailer.

| UV System | Monoray 1-220 SS |

| No. of Lamps | 1 |

| Max Flow Rate | 10m3/hour |

| Transmission Factor pr 10 mm, UVT | 60% |

| Calculated Dose at End of Lamp Lifetime | 38 mJ/cm2 |

| Reactor Material | Stainless Steel |

| Reactor Connections | DN100 |

| Lamp Lifetime | 16000 Hours |

| Power | 0.2 kW |

| Cabinet Material | SS AISI304 |

| Control Cabinet Type | Standard |

| HMI | Four Line LCD with Multicolour Backlight |

| Individual Lamp State Indication | Yes, HMI Graphics |

| Automatic Wiping System | Yes |

| Parameter | Influent | Effluent |

|---|---|---|

| Max Design flow | 5,000 l/h | 5,000 l/h |

| BOD | 20 mg/l | 10 mg/l |

| Suspended Solids | 30 mg/l | 10 mg/l |